Proven techniques in New Jersey tank testing

Tank testing helps determine the integrity of your tank, and whether or not it’s safe to continue using. If the tank isn’t safe, Norroc can recommend repairs or remove the tank so it doesn’t cause any further damage to the building, soil and groundwater. Typically issues that arise after tank testing are related to the fill, vent, and supply piping. Corrosion to the threads of the piping, or loosening of the pipes over time, can produce a failed result during the test. Damaged sensors and gauges can also affect the test and need to be replaced. Norroc can repair these issues quickly so that your fuel system is ready to be brought back on line with little or no down time.

Since testing cannot predict what will happen to the tank next year, next month or even the next day, you may want to consider replacing an underground tank with an aboveground tank.

Underground storage tank testing

The most common tests for underground storage tank testing in New Jersey vacuum testing, and subsurface investigation.

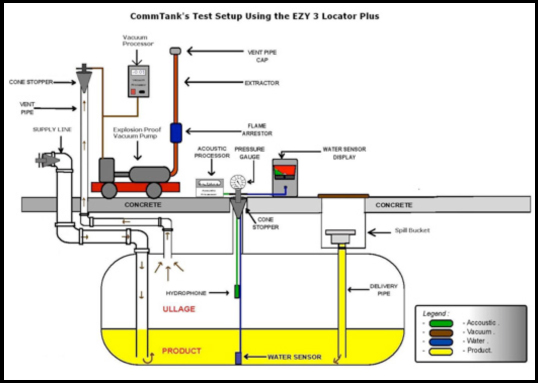

Vacuum testing is the safest method for testing tanks that are currently in service. Fluid in a tank exerts pressure on the sidewalls of the tank so adding extra pressure could exceed the manufactures limit or exacerbate an existing problem. Vacuum testing is safe because it offsets the pressure exerted by the fuel on the bottom of the tank. Once the vacuum creates an equalization of pressure, a failing tank will lose vacuum and take in air or water from the area outside the tank and a sound tank will hold vacuum. Norroc uses the EZY 3 Locator Plus system, which is a non-volumetric acoustical system. The EZY 3 Locator Plus consists of a microphone placed in the ullage of the underground tank. The microphone is connected to the acoustic signal processor and to a head set enabling the test operator to listen to the acoustic sounds in the tank. Using the motor/blower assembly a slight negative pressure is applied to the tank system, air and/or water will be drawn into the tank if a leak exists. These acoustic signals are recognized by a certified testing operator and characterized as an ullage portion leak/hiss sound or product portion leak/bubble sound. If ground water is above the tank bottom, the conductive water sensor will be used.

The issues that limit volumetric and mass measurement technology have no impact on acoustic based systems.

Benefits of the EZY 3 Locator Plus system compared to other test systems:

- Does not require a specific capacity during test – the tank can be empty or 99% full

- Does not require a temperature stabilization period

- Tests the tank, vent piping, fuel supply and return lines

- Meets or exceeds U.S. EPA accuracy requirements for tank testing

- Produces test results in one hour